stainless steel pricelist

Home

Home- · kitchen plinth sealing strip factory

- · shower frame seal strip exporter

- · sealing strip products

- · d shaped rubber seal strip product

- · oem window rubber seal strip

- · door bottom threshold seal strip pricelist

- · sponge seal tape companies

- · oem door rubber seal strip

- · corner shower door seal strip pricelist

- · silicone rubber plastic strip exporters

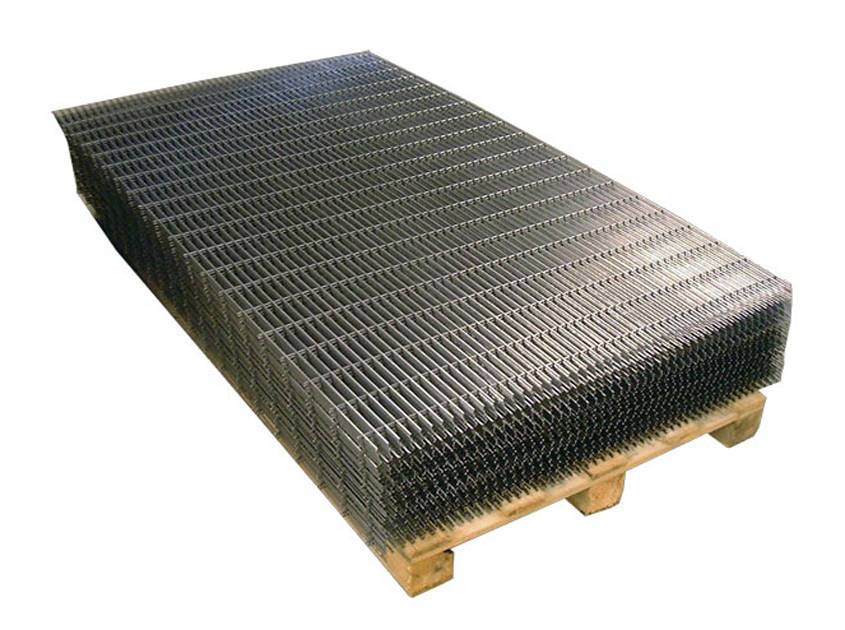

They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management

They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management Moreover, its durability and resilience make it ideal for outdoor installations where it is exposed to varying weather conditions Moreover, its durability and resilience make it ideal for outdoor installations where it is exposed to varying weather conditions

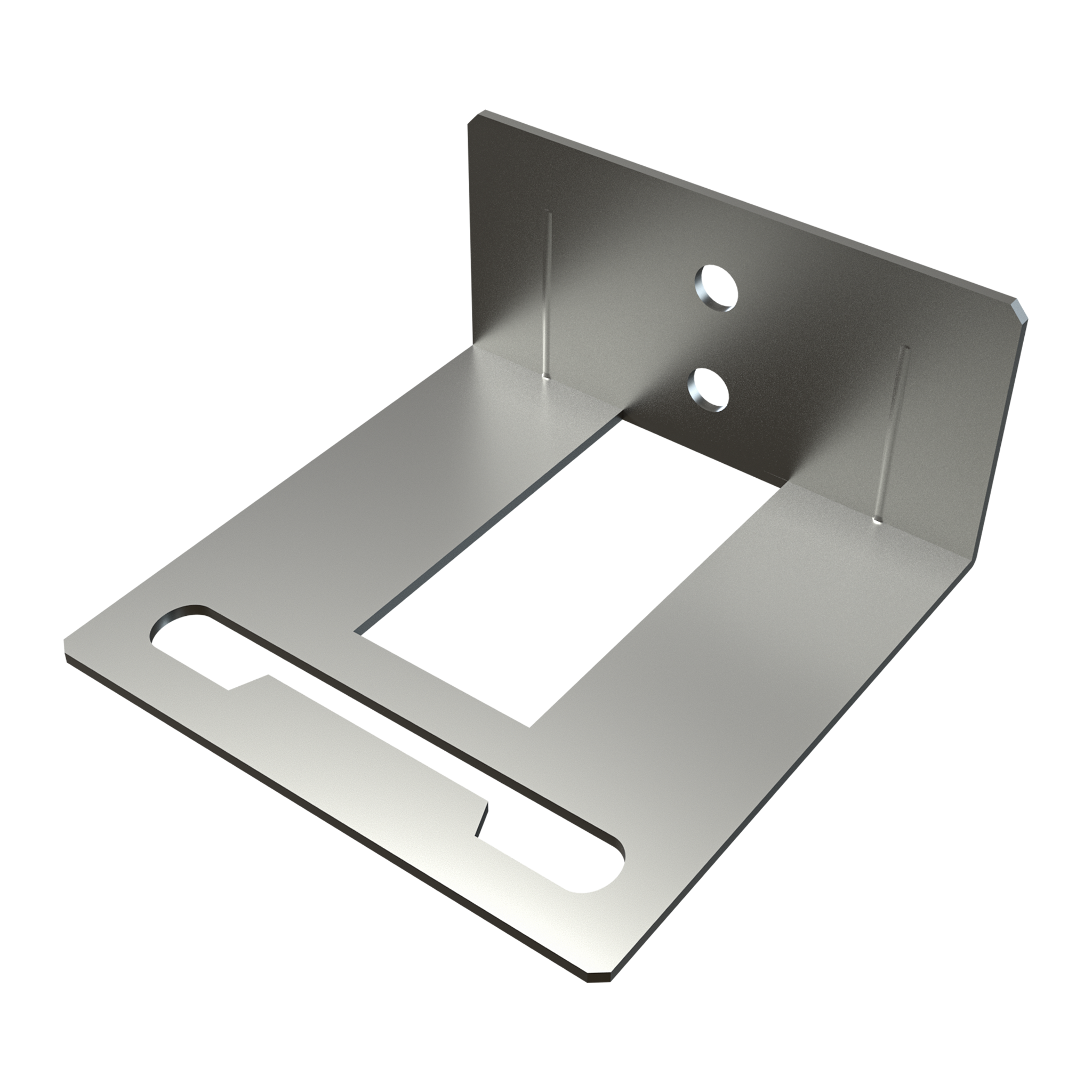

Moreover, its durability and resilience make it ideal for outdoor installations where it is exposed to varying weather conditions Moreover, its durability and resilience make it ideal for outdoor installations where it is exposed to varying weather conditions Additionally, custom-designed panels may incur additional costs due to the specialized nature of the design Additionally, custom-designed panels may incur additional costs due to the specialized nature of the design

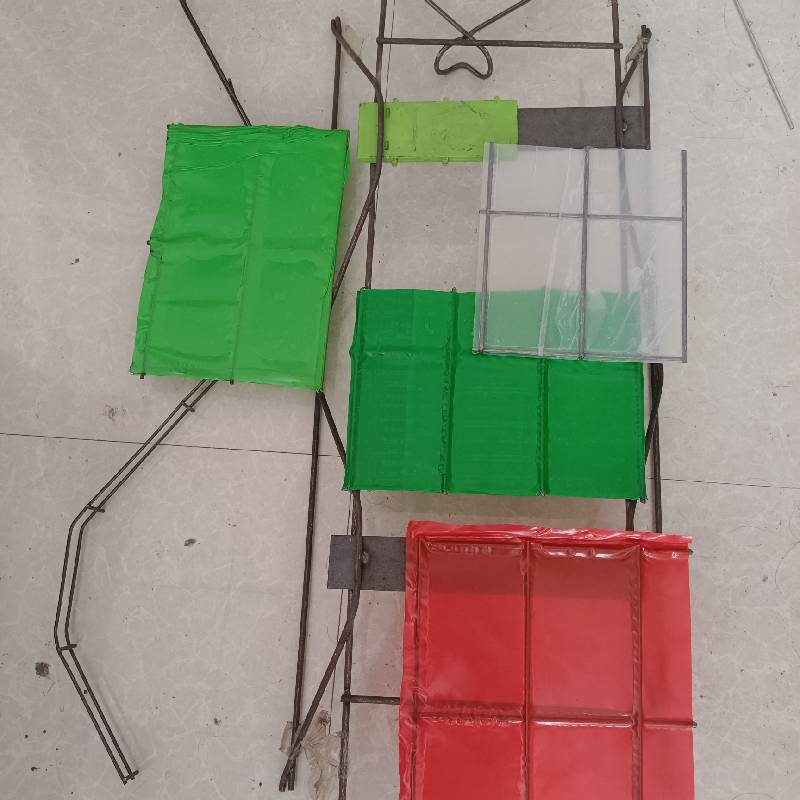

Additionally, custom-designed panels may incur additional costs due to the specialized nature of the design Additionally, custom-designed panels may incur additional costs due to the specialized nature of the design Just as the sign holder could present two different messages, so too could we embody multiple roles and emotions without compromising our essence Just as the sign holder could present two different messages, so too could we embody multiple roles and emotions without compromising our essence

Just as the sign holder could present two different messages, so too could we embody multiple roles and emotions without compromising our essence Just as the sign holder could present two different messages, so too could we embody multiple roles and emotions without compromising our essence For instance, it can be used as a decorative element in gardens or landscaping projects For instance, it can be used as a decorative element in gardens or landscaping projects

For instance, it can be used as a decorative element in gardens or landscaping projects For instance, it can be used as a decorative element in gardens or landscaping projects They are designed to withstand repeated use and high levels of stress without losing their shape or performance They are designed to withstand repeated use and high levels of stress without losing their shape or performance

They are designed to withstand repeated use and high levels of stress without losing their shape or performance They are designed to withstand repeated use and high levels of stress without losing their shape or performance Its resistance to rust makes it an ideal choice for farmers who need reliable and long-lasting solutions in their operations Its resistance to rust makes it an ideal choice for farmers who need reliable and long-lasting solutions in their operations

Its resistance to rust makes it an ideal choice for farmers who need reliable and long-lasting solutions in their operations Its resistance to rust makes it an ideal choice for farmers who need reliable and long-lasting solutions in their operations